In the trace elemental analysis industry, it is not uncommon for us to come across substances that we know will be complicated to analyze. At SGS, we don’t toss around the word “impossible” in our lab. We welcome challenges by having a “Bring It On” type of attitude. So, when we received DMSO samples for the first time earlier this year, our lab team did their research to ready the instruments (and themselves) for this difficult analysis.

First, what is it?

First, what is it?

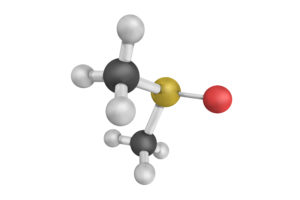

DMSO, or dimethyl sulfoxide, is an oily, colorless organosulfur compound with the chemical formula C2H6OS. It has a relatively high melting point and is considerably less polar than water. This makes it a favorite consideration for dissolution of materials which are not immediately solubilized in aqueous/acid matrices without heat. Earlier versions of the USP <233> monograph include a flow chart which first called for solubilization of materials in an aqueous medium and secondarily in an organic solvent (such as DMSO). Only after eliminating these options were closed vessel microwave digestions referenced for use.

What is it used for?

DMSO has been used as a reaction solvent in the making of drug compounds as well as an important excipient in pharmaceutical forms. Scientists enjoy using DMSO for its solvating properties in the formation of drug delivery technologies through topical and transdermal applications. In addition to being approved as an active pharmaceutical ingredient (API), it is also used as a cryopreservative (prevents cellular damage when preserving cells).

How did SGS handle DMSO?

Analysts at SGS run DMSO samples on our Perkin Elmer Nexion instruments after various adjustments are made to the instrument’s system, specially-heated spray chambers with oxygen introduction and protective vacuum system filters are necessary to prevent system damage caused by this material. We also utilized a unique torch and injector combination to eliminate the need for O-rings in the introduction system which are adversely affected by the DMSO. Carefully selected cones, nebulizers and DMSO resistant tubing are also necessary changes to the traditional ICP/MS setup.

What are the results?

After consultation with vendors and industry resources SGS initiated a series of experiments which lead to successful USP <233> validation of an extended elemental impurities testing method for DMSO. Validation results are shown in the following tables from a DMSO based material using Parental Limits and a 10-gram serving size.

Accuracy:

Activity: Control Sample spikes at 3 levels for each element of interest.

Acceptance: 80 – 120% recovery for each spike.

Accuracy (cont.)

Activity: 3 Test Samples spiked at 3 levels for each element of interest.

Acceptance: 70 – 150% recovery for the mean of 3 replicates at each concentration.

Precision/Repeatability

Activity: 6 Test Samples spiked at spiking level 2.

Acceptance: % Relative Standard Deviation (RSD) NMT 20.0 %

Intermediate Precision/Ruggedness

Activity: A second set of 6 test samples spiked at level 2 prepared by a second analyst and run by a second analyst on a second day.

Acceptance: % Relative standard Deviation (RSD) overall for both sets of precision samples NMT 25.0 %

To learn more about analyzing DMSO, or SGS’s capabilities in general, feel free to contact us and speak with our technical team. We may be reached at (717) 697-7536, or by emailing SGS_CSL_info@sgs.com – whichever you prefer!